ION DISTRIBUTION UNIT for GROUND USE AIRCRAFT INTERIOR PURIFICATION

Image: Screen Shot from ACA Aviation Clean Air website

Aviation Clean Air社とInternational Aero Engineeringは、航空機内部を消毒する地上使用専用のポータブル・イオン・分配ユニットとしてACAイオン化浄化システムを提供する為提携します。

このユニットはFAA Supplemental Type Certification(STC)によって航空機の設置が認定されている、ACAの特許取得済みの航空機搭載システムと同じテスト済みで実証済みのテクノロジーを使用します。

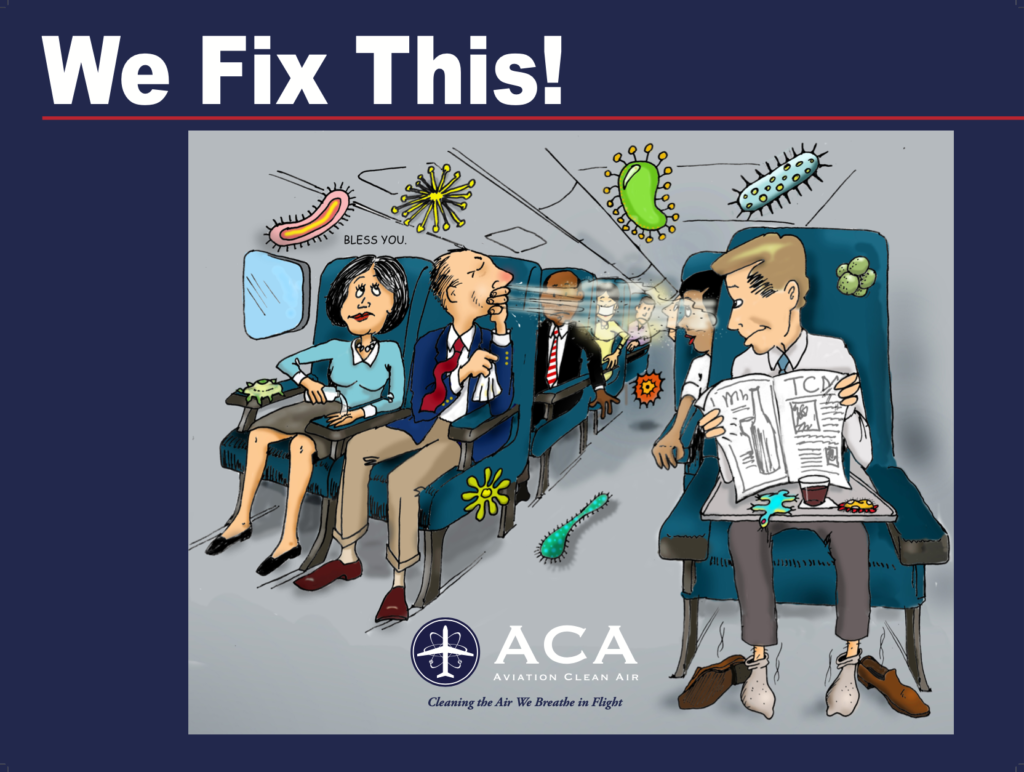

COVID-19の影響で航空機、関連施設等の環境浄化の必要性が高まっています。このシステムにより、航空機のオペレーターとメンテナンス施設に、機内を効果的に除染し、メンテナンス人員だけでなく乗客と乗務員の健康を保護するために実証済みのソリューションを提供します。

Aviation Clean Air (ACA) introduces a stunning new air and surface purification system for aircraft providing immediate clean, safe and healthy interior air by eliminating odors and allergens — including the common cold viruses – and, at the same time, provides interior surface purification throughout the entire cabin for business and commercial aviation.

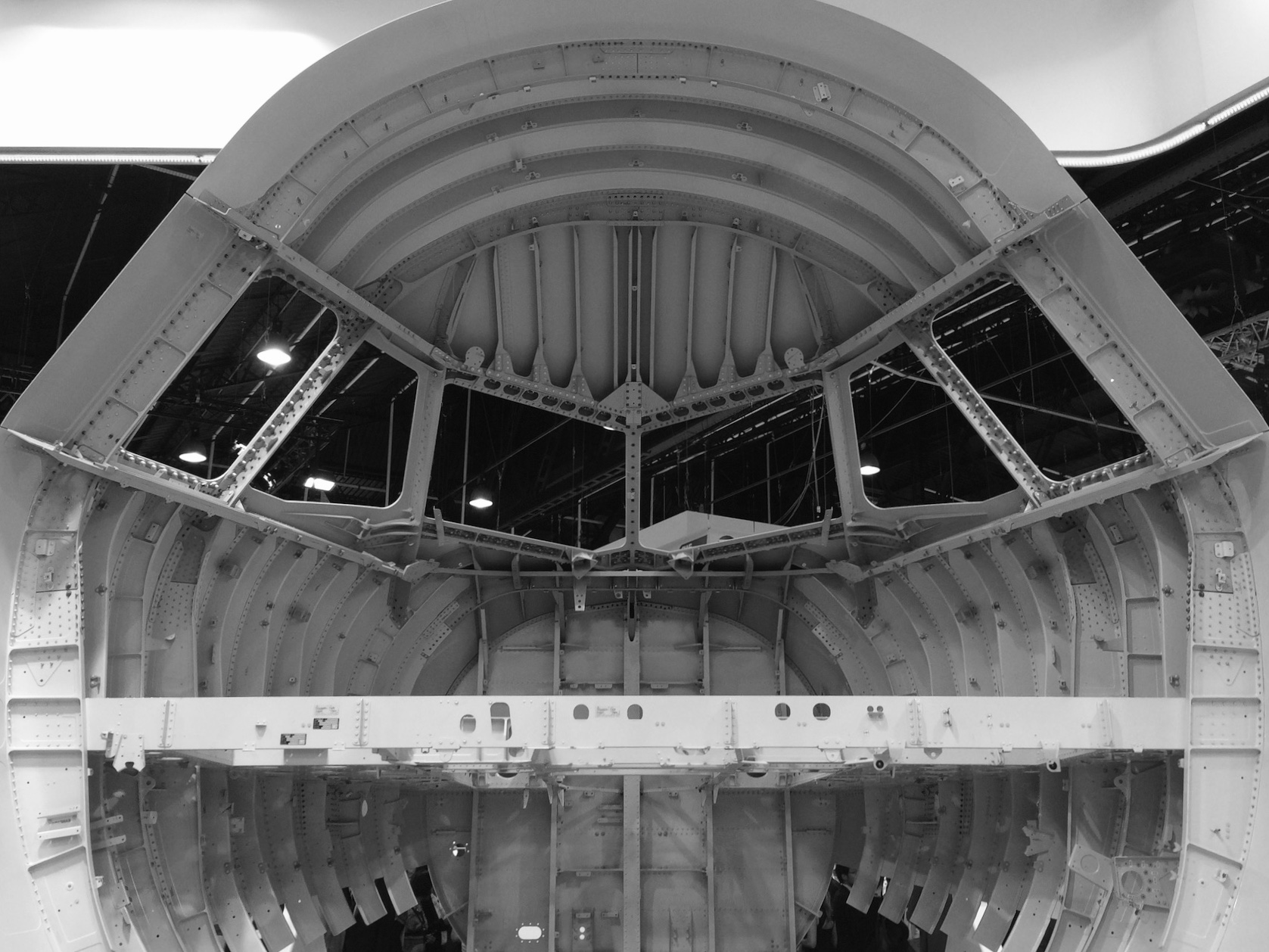

Image: ACA Aviation Clean Air website

通常機内に設置されたこのイオン発生器(proactive bipolar ion distribution system)は、ダクト内に取付けられ、空気を送り込み機内全体にイオンを分配することで病原菌を殺菌し、機内の空気と内装表面を浄化させるシステムです。電子的に生成された+イオンと-イオンは、空気中に存在する水蒸気中の水素分子と酸素分子から形成され、機内空気と内装の表面を浄化する洗浄剤として機能します。この技術は空気中のウイルスや、機内内装に付着したウイルスを不活性化させる自然の浄化作用を、人工的に複製し、加速させます。

ACAとInternational Aero Engineeringによって開発された地上ユニットは、ポータブル110 VAC電動イオン化および送風機ユニットで、機内の床に設置し、1〜2時間程で除菌を行うものです。除菌が完了したらユニットの電源を切り機体から取り出します。

これを使用することで、除菌済みの機体で、グラウンドクルーやその他の作業者が機内で通常の業務を行うことができるようになります。イオン化ユニットは、航空機の消毒と浄化に加えて、多くのOEM航空機整備施設で現在実施されている検疫要件にも役立つものと期待されています。

メーカーホームページには、同社製品が「殺菌」(Kills)、「抑制」(Controls)、「除く」(Removes)、「中和」(Neutralizes)する物質に関しての例が掲載されています。

SUMMARY:

Kills – The Common Cold Viruses (一般的風邪ウイルス)

Kills – Bird Flu Virus (H5N1) (鳥インフルエンザウイルス(H5N1))

Kills – Swine Flu Virus (H1N1) (豚インフルエンザウイルス(H1N1))

Kills – SARS Bacteria (SARSバクテリア)

Kills – Staph Bacteria (ブドウ球菌)

Kills – Mold Spores (カビ胞子)

Kills – MRSA, (methicillin‐resistant Staphylococcus aureus メチシリン耐性黄色ブドウ球菌)

Kills – E.coli, (enteropathogenic Escherichia coli 病原性大腸菌)

Kills – T.B. (tuberculosis 結核菌)

Kills – C.diff and more… (Clostridium difficile ディフィシル菌)

Controls – Allergens (アレルゲン)

Controls – Gases (ガス)

Controls – Volatile Organic Compounds (揮発性有機化合物)

Removes – Pet Odors (ペット臭)

Removes – Cooking Odors (料理臭)

Removes – Cigar and Cigarette Smoke (葉巻やタバコ煙)

Removes – Moisture Odors (湿気臭)

Neutralizes – Static Electricity (静電気)

ACA Air and Surface Purification System

Image: Provided by ACA Aviation Clean Air

メーカーニュースリリースより:

Proven Aircraft Interior Purification System AdaptedforGroundUse

March 19,2020, Savannah, GA…Aviation Clean Air (ACA) and International Aero Engineering have partnered to offer the ACA Ionization Purification System as a portable Ion Distribution Unit for Ground Use Only for proactivelydisinfecting aircraft interiors. The unit utilizes the same tested, proventechnology as ACA’s patented airborne system, which is certified for aircraft installation by FAA Supplemental Type Certification (STC). The new Ion Distribution Unit has been adapted to meet the immediate need for decontaminating aircraft interiors while on the ground. The system provides aircraft operators and service facilities a proven solution to effectively decontaminate aircraft interiors and protect the health of maintenance personnel as well as passengers and crew.

The proactive bipolar Ion Distribution system kills pathogens and purifies the air and surfaces bypushing air through the cabin and distributingions throughout the aircraft interior. The electronically created positive and negative ions form from hydrogen and oxygen molecules in the water vapor present in the air and work as a cleaning agent to purify the air and surfaces. The technology replicates and acceleratesnature’scleaning process that successfully inactivates airborne and surface viruses.

The ground unit developed by ACA and International Aero Engineering is a portable, 110 VACelectric-powered ionization and air blower unit that is placed on the floor of the cabin and activated for a period of time, ranging from one to two hours. Upon completion, the unit is powered off and removed from the aircraft.Ground crew, technicians and other personnel can then confidently enter the aircraft and perform their normal functions. In addition to disinfecting and purifying the aircraft, the ionization unit eliminates the quarantine requirement currently in place at many OEM aircraft maintenance facilities.

“We have been working with aviation manufacturers, operators and service companies for many years, and we know how important it is to them and their customers to continue to keep the industry functioning, while also being vigilant about the current situation,” said Jonathan Saltman, International Aero President and CEO. “The partnership with Aviation Clean Air, who has established industry relationships as well, allows us to provide a much-needed solution to effectively and efficiently deal with the enhanced levels of decontamination being undertaken.”

“OurIonization Purification System has been installed on a variety of aircraft models and is proven to purify the air and surfaces onboard,” said Howard Hackney, ACA Managing Member. “Adapting the system for ground use provides not only effectivecleaning and disinfecting of aircraft interiors, it offers a number of advantages. The proactive, natural purification process uses no chemicals and produces no harmful ozone or other emissions. It will also not damage fabrics or carpeting, as other disinfectants potentially could. In addition, it lessens the number of personnel required and downtime needed to conduct a thorough disinfection.”

参照リンク:

https://www.aviationcleanair.com/